That looks like a lot of work, good luck!

To answer your questions I would suggest leaving the sander alone until you stripped the paint using a hot air gun and scraper. Use as little heat as poss and a pull scraper with the grain trying not to dig the corners in. Sanding the paint will just clog the paper. Use the sander with 120 paper to clean the scrapes and last bits of paint away, then hand sand with a block to remove the swirl marks the sander leaves behind.

Before you start all that though, take a step back and think about how you might use such a classic Fireball when it does reach the water. If you intend to modernise the rig setup and use it as a racing machine even at a modest club level, it will need some structural work to make it stronger, and a lot of money spent on pulleys and ropes! Decide on the rig systems first, then rebuild the boat around them. Don't even think about paint and varnish till you know where everything fits and all the fixing points are ready.

With any Spinnaker trapeze boat, the key to enjoyment is making it work - Reliably. On a screaming spinnaker reach, the last thing you want is something jamming on that sticky-out fitting that always gets in the way, or vital parts flying off with their 1/2" screws attached. It can get Dangerous at that speed!!!

As well as my Moth, I sail a 1987 wood Fireball. Its still a bit too new to be CVRDA eligible, but when driven hard enough it beats many brand new plastic boats. We still use a chute, and its quicker and more reliable than bag system if you sail mostly on flat water. The only disadvantage is in a choppy sea when it funnels water in very efficiently.

Older boats were not built to withstand anything like the rig tension that a modern rig needs. If you check the layout of later wooden boats and especially the FRP Winders you will see lots more bulkheads and bracing which triangulate the load from mast, shrouds and jib, and support the centreboard case. Without that bracing the boat can literally split apart if overstressed, so its worth building in while the boat is stripped. Plywood on edge with epoxy fillets is immensely strong and light. I would consider re-decking at least the front half in order to add the strengthening, especially if you do decide to remove the chute.

As for the rig and systems, have a look at the Draycote Fireball website. There are lots of pictures and explaination of bag and chute systems, and rigging guides.

http://www.draycotewater.co.uk/fleets/fireball/

Lyndon

Fireball 13918

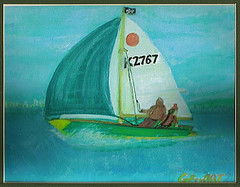

I did this little pic of the first one after I sold her, I was doing more river boat cruising at that time but have to say I really was sorry for the first time before or since, to see a boat go.

I did this little pic of the first one after I sold her, I was doing more river boat cruising at that time but have to say I really was sorry for the first time before or since, to see a boat go.

Slick Willey never seemed the same, built by Milne in Perth Australia, I gather he(ol slick) was a junior champ winning boat maybe too good for my limited abilities, mainly single handed, went after I bought a 57 Merlin Rocket, however the third which I brought back from Rainham, and later found not to have the right ply cuts to finish, didnt check beforehand all the old stuff on top, new beneath i got told hrmm, and just had a load of old decking.

Slick Willey never seemed the same, built by Milne in Perth Australia, I gather he(ol slick) was a junior champ winning boat maybe too good for my limited abilities, mainly single handed, went after I bought a 57 Merlin Rocket, however the third which I brought back from Rainham, and later found not to have the right ply cuts to finish, didnt check beforehand all the old stuff on top, new beneath i got told hrmm, and just had a load of old decking. Fortunately they have escaped a burn up!!!

Fortunately they have escaped a burn up!!!