Ok so the bailer repair is on hold until I can source some ply and enlist a friend to help turn her over

In the meantime, now my scrappers and heat gun have arrived, I plan to tackle the next big job which is removing epoxy and paint from the inside of the boat. So here is my question

Is there a risk of the ply warping once it is stripped?. I only get about an hour at a time to work on the boat, so it could well take me a long time (weeks) between strip and coating it again.

I ask this as the only other wooden restoration I have ever done was a table I found in a skip. I spent hours sanding it down to remove varnish, stains and large scratches, I then left it in the garage for a few weeks before I got the chance to re varnish it, when I discovered it had warped quiet badly.

Thanks in advance. Have been very impressed with the help I have received so far.

Stripping ply, question.

-

Michael Brigg

- Posts: 1663

- Joined: Fri Jul 06, 2007 7:11 pm

- Location: Gosport, UK

Re: Stripping ply, question.

Good quality ply will not warp, because it is a laminated structure, with epoxy glue sandwiched within the layers. The grain in each layer is orientated at a different angle in each layer, so the inclination to warp is "cancelled out" so to speak, and in fact any tension that builds up in the structure arising as a result of expansion within the layer, should, if anything , make it even stiffer.

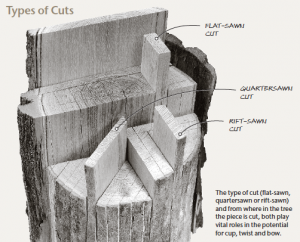

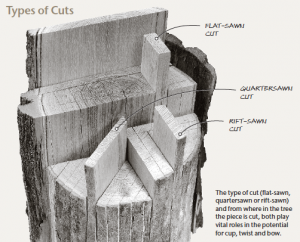

I contrast to this your table was quite probably made from solid wood. If the table surface was a really thick piece of wood, then there may inevitbly be some warp if it dries or becomes moister, which depends partly on the method used to cut the sections.

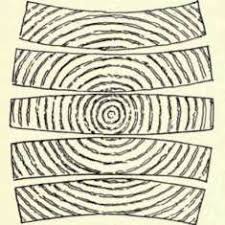

In any tree trunk there is only one perfect cut. This is the plank or section the is cut across the diameter of the trunk. from oter surface, through the centre, to the other side. This may be prone to split along imperfections in the centre. There are a variety of techniques to cut planking to maximize the yield of "straight" planks, though inevitably they will be narrower planks.

Different ways to cut planking.

Rather counter intuitively this means a clinker with fewer stakes is actualy (probably) built from better quality planking.)

Wood expands approximately 6 times more in its horizontal (coronal or sagittal) plane than in its longitudinal plane.

The problem is that is a plank is a cheaper cut then it has been taken further from the centre, on an Arc, rather than on the diameter. The curvature of the grain in such a cut will will mean that the grain is thicker on one side of the plank than the other, and so as the plank expands across its width, the thicker grain on one side will expand more, and in a different direction on one side compared with the other.

This might be reduced by seasoning the would but even this will not be enough. The only real answer is to make the wooden object in the conditions in which it will be used.

I contrast to this your table was quite probably made from solid wood. If the table surface was a really thick piece of wood, then there may inevitbly be some warp if it dries or becomes moister, which depends partly on the method used to cut the sections.

In any tree trunk there is only one perfect cut. This is the plank or section the is cut across the diameter of the trunk. from oter surface, through the centre, to the other side. This may be prone to split along imperfections in the centre. There are a variety of techniques to cut planking to maximize the yield of "straight" planks, though inevitably they will be narrower planks.

Different ways to cut planking.

Rather counter intuitively this means a clinker with fewer stakes is actualy (probably) built from better quality planking.)

Wood expands approximately 6 times more in its horizontal (coronal or sagittal) plane than in its longitudinal plane.

The problem is that is a plank is a cheaper cut then it has been taken further from the centre, on an Arc, rather than on the diameter. The curvature of the grain in such a cut will will mean that the grain is thicker on one side of the plank than the other, and so as the plank expands across its width, the thicker grain on one side will expand more, and in a different direction on one side compared with the other.

This might be reduced by seasoning the would but even this will not be enough. The only real answer is to make the wooden object in the conditions in which it will be used.

Michael Brigg

Re: Stripping ply, question.

Fantastic answer, thank very much, extremely educational.